Sieves and screens are widely used in pharmaceutical manufacturing as well as in the quality control to determine the particle size of the raw materials. Mesh is the most common measurement unit used for the sieves and screens.

Generally, 40 to 400 mesh sieves are used in pharmaceutical manufacturing during shifting and milling of raw material. Mesh is the number of openings in one linear inch of any sieve or screen. A 10 mesh sieve will have 10 openings and a 400 mesh sieve will have 400 openings in one linear inch.

The fineness of any sieve or screen depends upon the width of the wire used. The wire used in 10 mesh sieve will be thicker than the wire used in 60 mesh sieve. A thick wire can't make a fine sieve and a thin wire can't make a thick sieve. Fine sieves above 400 mesh, the particle size is described in microns.

For a material having fine particles, a fine sieve having a very small opening is used. The fineness of any sieve or screen increases when its mesh size increases and its pore size decreases.

Mesh to Micron Conversion Chart

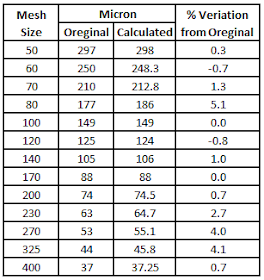

Following is the conversion table for the mesh to micron and inch.

Mesh to Micron Conversion Formula

There is no official formula to convert the mesh to micron and vice-versa. I have tried to develop a conversion formula that gives approximately the correct conversion from mesh to micron and vice versa.

Mesh x Micron =14900 (Approx)

Micron = 14900/mesh, and

Mesh = 14900/micron

It has some errors but it is still useful to get an approximate value while converting between 50 to 400 mesh. This variation is shown in the table.

Mesh and inches conversion can be done using the following formula.

Inch= 0.6/mesh

Mesh= 0.6/inch

It is a very simple method to determine the mesh size of any sieve or screen. Carefully mark the sieve for 1 inch using a permanent marker and scale. Measurement should be started from the center of the wire to make it more accurate. Count the number the holes in this area. The number of holes in one linear inch is known as the mesh. For example: if 60 holes are found in an inch then the sieve will be of 60 mesh. These holes can be counted using the marker pen.

Frequently Asked Questions on Mesh Size

Q: What is the purpose of converting mesh to microns?

Mesh and micron both are used to determine the pore size of sieves used in pharmaceutical manufacturing. Mesh size is determined by counting the number of pores in 1 linear inch while a micron is a standard unit of pore size. Conversion between each other allows accurate communication while talking about specifications.

Q: How do you convert mesh to microns?

There is no any standard formula to convert mesh to microns but we can roughly convert by dividing 14900 by the given mesh size (micron = 14900/mesh). For example, 60 mesh will be equal to 14900/60 = 248 microns.

Q: What is the relationship between mesh and particle size?

Mesh size and particle size are inversely proportional, which means when mesh size increases the particle size decreases and vice versa.

Q: Are mesh and microns the only units used for particle size?

No, there are many units of particle size measurement but in pharmaceuticals mesh and microns are widely used because of the requirement of precision and accuracy. Millimeter, nanometer and angstrom are other units used to measure particle size.

Q: Are there standard conversion charts for the mesh to microns?

Yes, there are some charts that provide the list of mesh to micron conversion. By using these charts anyone can convert mesh to micron and vice versa easily. A useful chart is given above for reference.

Q: Is it always accurate to convert mesh to microns?

No, mesh to micron conversion is not accurate but it is an approximate conversion. The conversion chart given above has calculated value and accurate original value.

Q: Why is particle size important in pharmaceuticals?

Particle size plays an important role in pharmaceutical formulations. Particle size may affect the dissolution and bioavailability of the product.

Why use 14900 as the approx in formula?

ReplyDeleteOk

ReplyDeletevery good information sir , we are glad.

ReplyDelete